Technological Scenario Envisaged |

| |

|

Expected performance of machine tools

|

|

-

-

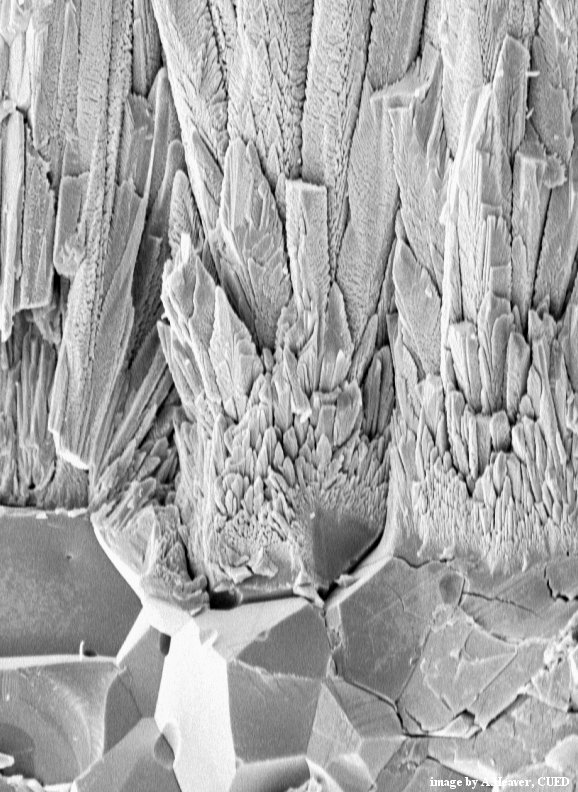

- PMC (reinforced carbon fibres) composite optimised for applications in the area of machine tools

- Sandwich structures based on PMC, honeycomb-Al and gluing

|

-

-

- Mass reduction of movable parts: −30%

- Machine axis acceleration = 20 m/s2

- Position accuracy = 5-10 µm

- Costs: still higher compared to conventional material solutions

|

-

-

-

- New light solution based on composite and hybrid materials including innovative polymeric matrix, reinforcement fibres, foams and damping materials

- Light and vibration free structures based on composite materials, microsensor and piezo-actuators

- Cost-effective design based on comprehensive overall approach

|

-

-

-

- Mass reduction of movable parts: −50%

- Machine axis acceleration = 25-30 m/s2

- Position accuracy = 1-5 µm

- Costs: toward cost-effectiveness

|

-

-

- Smart composites with innovative embedded actuators and sensors (active fibres, memory shape, MR fluids, ...)

- Multifunctional materials

- Interdisciplinary modelling analysis

- Smart mechatronic structures exploiting smart composites and adaptronics concepts for dynamic, thermal control and damage detections

|

-

-

- Mass reduction of movable parts: −60/−70%

- Machine axis acceleration = 30-40 m/s2

- Position accuracy = 1 µm

- Cost-effective solutions

|